Everything Starts With Secure Network Practices

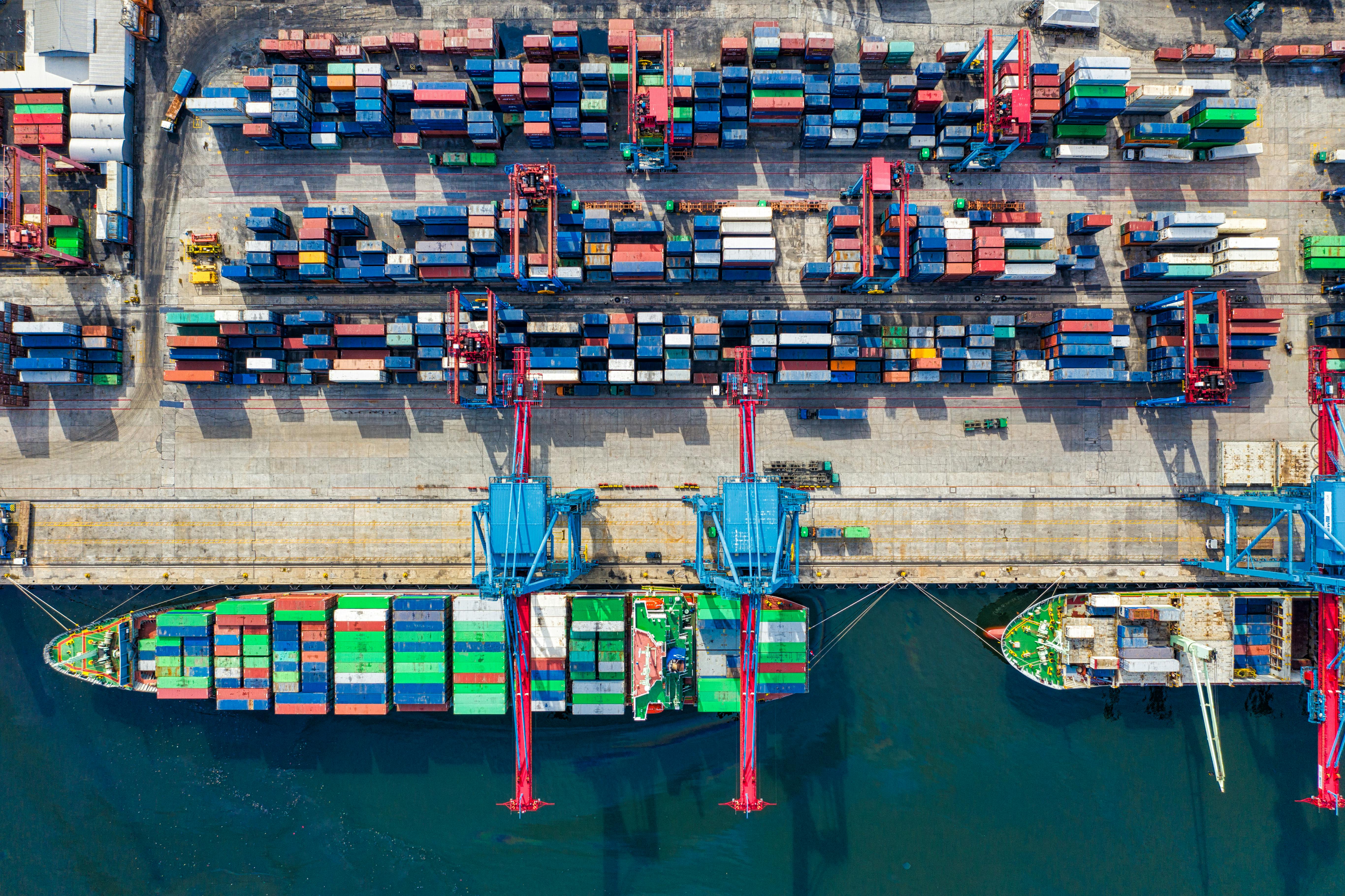

Supply chains are now software-defined systems that span clouds, partner networks, contractor laptops, and a growing fleet of connected devices.

That reach is a strength. It is also the reason a small gap in access control or outbound traffic can ripple into missed shipments, idle lines, or delayed tenders. Resilience in this setting is not a vague goal.

It is a network behavior you can see and measure. Healthy modern supply chains keep data flows predictable, identities strong, and third-party access bounded. When partners change, systems upgrade, or demand spikes, the network posture flexes but does not break.

At the end of this article you will be convinced that companies that treat network security hygiene as a production discipline, are the ones that keep trucks moving and planners informed when the unexpected hits.

Why private proxies anchor network hygiene in supply chains

In operational networks, not every system should talk to the outside world in the same way. That is where private proxies come in. A private proxy is a dedicated intermediary for outbound traffic that gives operations teams precise control over what leaves the network and how it looks to the destination. Unlike open or shared services, dedicated proxies provide stable addresses, tunable policies, and full logging, so supplier platforms can allowlist known routes while security teams watch, limit, and prove what happened.

The practical value shows up in day-to-day tasks. Procurement bots that gather price and lead-time data can be routed through one egress identity while engineering tools that pull BOM updates use another. Supplier portals often throttle or block traffic that appears to come from dynamic or shared ranges, so a dedicated proxy avoids false alarms. When an integration needs higher throughput, teams can scale a specific proxy path without opening the whole network. During cutovers, traffic can be canaried through a new route, measured, and then promoted, all without exposing core systems.

Mid-process is the right moment to consider whether to buy private proxy capacity rather than rely on general purpose or public endpoints. Dedicated options let you align egress to business processes. You can bind certain proxies to machine identities, require mutual TLS, and attach data loss prevention checks for files leaving PLM or ERP. Because each route has a stable IP and policy, supplier SOC teams can trace activity to a single integration rather than a shifting pool. That lowers friction when you need to prove the integrity of a transaction or explain an unusual spike.

The measurable side of resilience

Recent data shows how third-party exposure and slow patching can widen risk, while disciplined network control helps close it. The figures below set helpful benchmarks for supply chain leaders.

| Indicator | Latest figure |

| Breaches with third-party involvement | 30% in 2025, up from 15% the year before |

| Average total cost of a data breach | USD 4.88 million in 2024 |

| Ransomware present in breaches | 44% in 2025 |

| Perimeter device vulnerabilities fully remediated, median time | 54% remediated, 32 days median |

| Large organizations citing supply chain as top barrier to cyber resilience | 54% in 2025 |

Data sources: Verizon, World Economic Forum, IBM

Operational design that scales

Resilience rises when secure network practices are built into the operating model. Start by baselining outbound flows for each supply process. Map which systems fetch drawings, submit ASN data, or query vendor inventory, then route each stream through a dedicated egress identity with rate limits and data checks. Keep proxy addresses stable so suppliers can allowlist them, and tag every flow with a business owner to speed triage.

External evidence backs this focus. The World Economic Forum notes that “supply chain vulnerabilities are emerging as the top ecosystem cyber risk,” with most large organizations calling supply chain issues their biggest barrier to resilience. That is a clear mandate to tighten partner access and make traffic provenance obvious.

Signal-driven monitoring closes the loop. If partner incidents are climbing, as recent procurement surveys report, you want alerts tied to the business process, not just to IPs or ports. That way a spike in failed logins at a supplier portal pages the integration owner who can pause a single proxy route, not the whole plant network.