Apple doesn’t just lead the tech world with sleek products—it dominates supply chain strategy with equal precision.

From the iPhone to Apple TV, the company’s tightly orchestrated global operations have become a gold standard for electronics manufacturers. As supply chains face mounting complexity—from shifting trade policies to AI integration—Apple’s approach remains a critical benchmark.

In this article, we’ll break down the pillars of Apple’s supply chain innovation and explore why operations leaders across the electronics sector study its methods. You’ll gain insight into the tools, systems, and strategies Apple uses—and what your brand can learn from them.

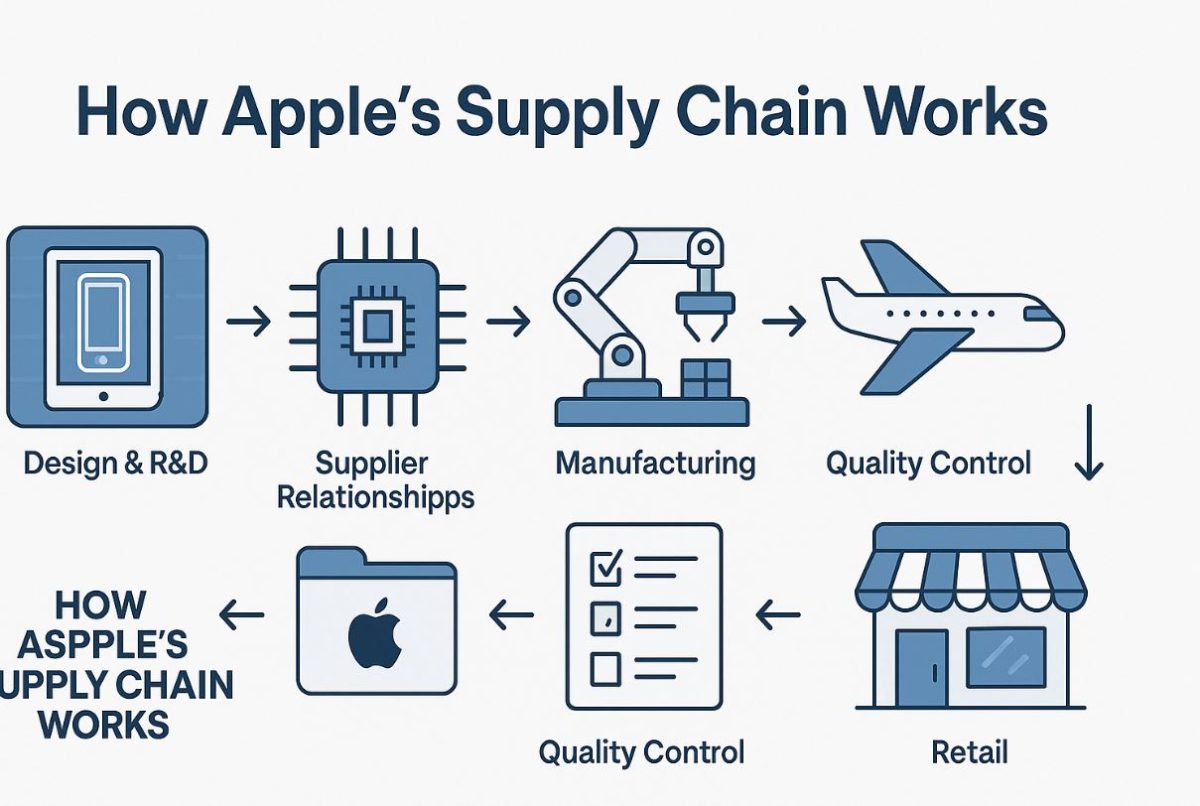

The Core Pillars of Apple’s Supply Chain Success

Strategic Supplier Partnerships

Apple’s relationships with suppliers go far beyond standard procurement. Rather than working with hundreds of fragmented vendors, Apple fosters high-value, long-term partnerships. Foxconn, TSMC (Taiwan Semiconductor Manufacturing Company), Murata, and Pegatron are integral to its operations.

By involving suppliers early in product design and development, Apple increases efficiency and shortens product lifecycles. This collaborative model creates a level of predictability that few other brands enjoy.

🧠 Insight: A 2024 Deloitte survey showed that companies with integrated supplier collaboration reduced new product launch times by up to 20%.

Vertical Integration and In-House Control

Apple’s tight control over core technologies like the M-series chips gives it a unique edge. Vertical integration helps Apple:

- Reduce latency between design and production

- Manage costs more precisely

- Safeguard proprietary innovations

Unlike competitors who depend on generic third-party parts, Apple can align its hardware and software development with supply chain execution.

Just-in-Time (JIT) Inventory Models

Apple’s JIT inventory system is supported by its global forecasting models and real-time sales data. In 2023, Apple reduced its on-hand finished goods inventory by 12% despite global supply fluctuations—a testament to the accuracy of its demand planning systems.

Moreover, the company has built flexibility into this model. It can reroute components from slower-selling products to higher-demand ones dynamically through its supply network, minimizing stockouts and overstocks.

Spotlight on Apple TV & Consumer Electronics Logistics

From Chip to Living Room: Apple TV’s Journey

Apple TV’s production life cycle touches multiple countries:

- Design – Cupertino, California

- Chip Manufacturing – Taiwan (TSMC)

- Component Assembly – China, India, Vietnam

- Distribution – Global via a network of air freight and local logistics partners

Each Apple TV unit embodies a global orchestration of parts, manufacturing, and shipping. From Taiwan to India to your living room, Apple ensures consistency in performance. But when it comes to content access, users in different regions often face restrictions due to licensing and platform limitations. That’s why many viewers choose to use X-VPN as their Apple TV VPN solution to unlock geo-restricted content across regions, ensuring seamless access to streaming libraries worldwide.

Managing Complex Multi-Country Assembly

Apple’s multi-country assembly strategy serves multiple goals:

- Diversification – Reduces geopolitical risk

- Efficiency – Localizes production closer to high-demand regions

- ESG Goals – Allows better oversight of ethical manufacturing practices

By 2025, Apple is expected to produce 25% of all iPads and Apple TVs in India, and that percentage is projected to grow.

Digital Innovation in Apple’s Supply Chain

AI, Automation & Predictive Analytics

Apple has embraced predictive AI for everything from demand forecasting to equipment maintenance. Here’s how:

- AI Forecasting Models predict product demand based on historical data, pre-orders, and social media trends.

- Machine Learning Algorithms adjust factory schedules based on late component arrival alerts.

- Automation in warehouses accelerates fulfillment and reduces error rates.

Apple’s smart factories also use digital twins—virtual replicas of supply chain systems—to simulate and optimize decisions before executing them in the real world.

Real-Time Monitoring & Supplier Visibility

Apple employs end-to-end tracking for materials across its supply chain using IoT sensors and ERP platforms. This enables:

- Early risk detection

- Supplier compliance scoring

- Inventory tracking across continents

In parallel, as supply chain teams operate from distributed global locations, many organizations turn to encrypted tunneling tools to maintain secure access to region-specific resources. Tools that offer a secure connection to US-based servers are especially valuable when managing assets tied to North American infrastructure or data compliance.

Apple’s Ethical and Sustainable Supply Chain Practices

ESG Reporting and Carbon Neutral Goals

Apple’s 2030 supply chain carbon-neutral target includes:

- 100% renewable electricity usage by suppliers

- Carbon offsets through reforestation and carbon capture

- Closed-loop material sourcing

Apple now publishes an annual Environmental Progress Report, which in 2024 reported that 75% of suppliers already use clean energy.

Stat: According to CDP (Carbon Disclosure Project), Apple ranked in the top 1% for environmental transparency and governance among S&P 500 companies.

Conflict-Free Materials & Fair Labor Standards

Apple audits 100% of its supplier factories annually. Suppliers that violate ethical labor standards risk termination. It also demands conflict-free sourcing of cobalt, tungsten, tin, and gold—essential components in Apple TV and other devices.

Apple works with NGOs, third-party auditors, and local governments to improve labor standards and increase traceability of materials used in its devices.

How Apple Responds to Global Supply Chain Disruptions

Resilience Through Diversification

Apple’s ability to adapt to crises like the global chip shortage of 2020–2022 offers a powerful case study. It:

- Pre-bought supply capacity from chip manufacturers

- Shifted production from China to Vietnam and India

- Accelerated the redesign of products using more readily available components

By proactively redesigning boards and switching to new suppliers, Apple avoided the long backlogs that plagued its competitors.

Crisis Planning and Scenario Modeling

Apple uses scenario simulation tools within its SCM software to plan for:

- Natural disasters

- Factory shutdowns

- Raw material shortages

- Geopolitical instability

These tools run risk analysis simulations, allowing teams to prepare contingency plans and alternative sourcing routes in advance.

Lessons for Mid-Sized Consumer Electronics Brands

What Can Be Emulated?

- Strategic Sourcing – Focus on deeper supplier relationships, not more suppliers.

- Forecasting Tech – Integrate basic AI forecasting into demand planning.

- Transparency Tools – Use cloud-based SCM tools like SAP S/4HANA or Oracle SCM Cloud to improve visibility.

Barriers and Considerations

Not every company can afford Apple’s infrastructure. Smaller brands must:

- Balance in-house vs. outsourced tech

- Invest in people just as much as software

- Prioritize modular and regional manufacturing to remain agile

Still, Apple’s blueprint shows what’s possible—even on a smaller scale—with disciplined processes and innovation investment.

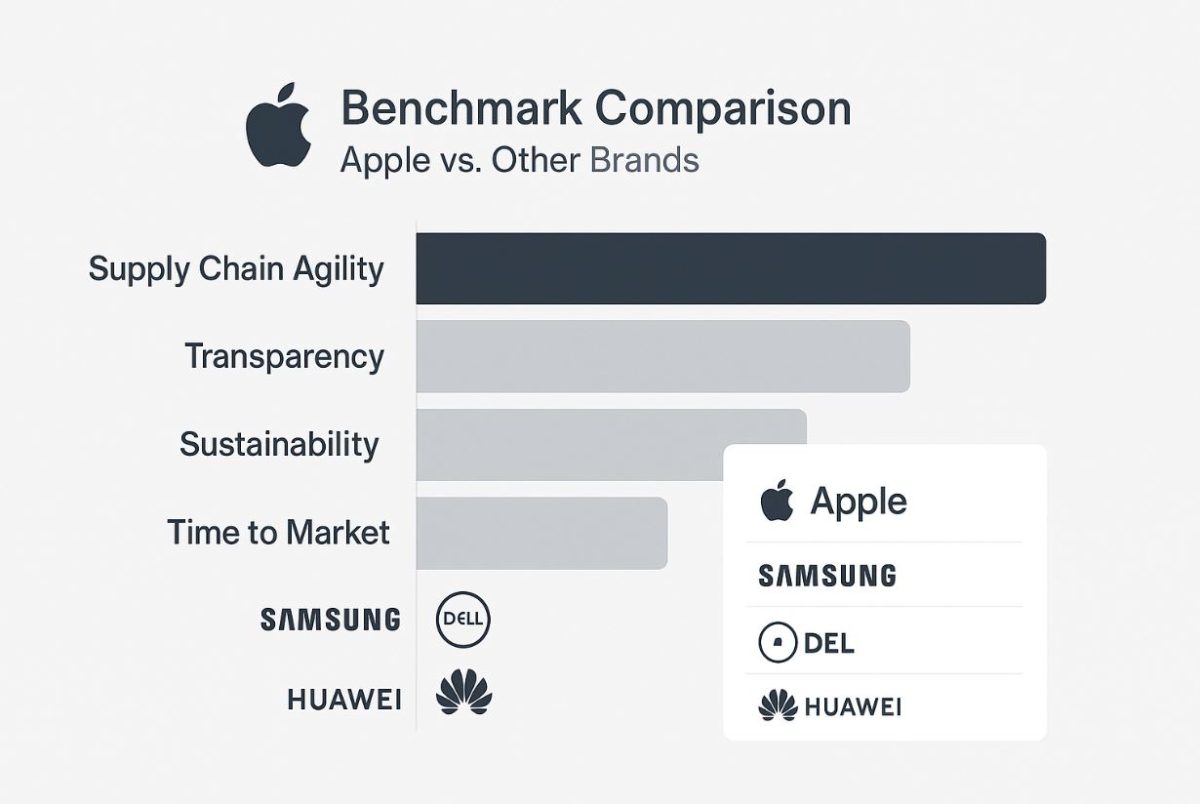

Conclusion: The Future of Supply Chain Benchmarking

Apple’s supply chain isn’t just a business function—it’s a competitive weapon. By combining strategic partnerships, AI-driven logistics, ethical oversight, and global agility, Apple has redefined what excellence in supply chain management looks like.

For consumer electronics brands looking to scale, the message is clear: benchmark against the best, but customize for your reality. Learn from Apple’s playbook, but adapt it to your size, market, and capabilities.