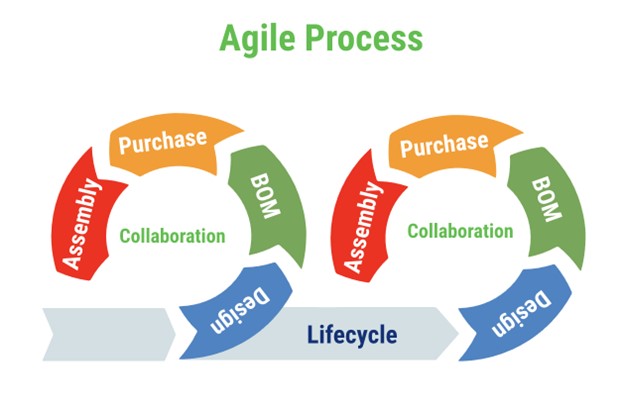

Supply chain collaboration involves businesses working together to improve the flow of goods and information. By sharing data and coordinating actions, companies can boost efficiency and cut costs.

This collaboration enhances decision-making and builds stronger partner relationships. In 2025, the right software will be crucial for optimizing these processes.

This article explores the ins and outs of supply chain collaboration, its benefits, and tips on choosing the best software.

Key Takeaways :

● Supplier collaboration software enhances communication and visibility among supply chain partners, leading to improved decision-making and operational efficiency.

● Key benefits of utilizing supplier collaboration tools include cost reduction, increased innovation, and the ability to respond proactively to supply chain disruptions.

● Selecting the right platform involves assessing organizational needs, ensuring ease of use, and leveraging real-time data sharing and AI-powered analytics for optimal performance.

Understanding Supply Chain Collaboration Software

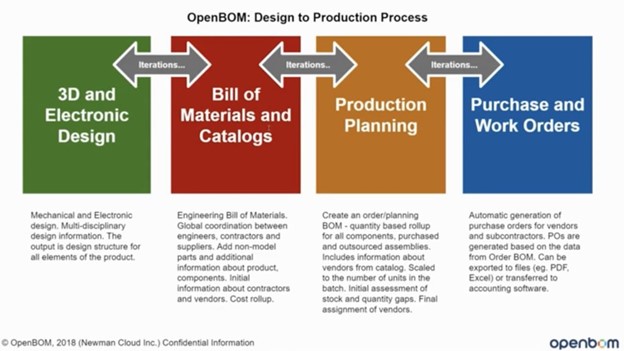

Supplier collaboration software is a digital solution designed to streamline communication, coordination, and collaboration between companies and their vendors. Imagine a central hub where all your supply chain partners can interact in real-time, share information, manage transactions, and streamline processes. This is the essence of supply chain collaboration software, providing a unified platform for seamless interactions.

One of the key features of supplier collaboration software is its ability to enable real-time collaboration among supply chain partners. With this technology, businesses can involve their suppliers in decision-making processes, ensuring that trading relationship attributes are managed effectively. This fosters a culture of mutual decision-making and trust, which is essential for effective supply chain collaboration.

Moreover, supplier collaboration software enhances supply chain visibility by providing a centralized hub for real-time interaction and information sharing. Unifying data platforms allows businesses to enhance the flow of information, materials, and goods across the supply chain, resulting in tighter coordination and increased productivity. This end-to-end visibility is crucial for managing supply chain disruptions and maintaining operational efficiency.

Key Benefits of Supplier Collaboration Software

One of the primary benefits of supplier collaboration software is the enhancement of communication, which strengthens demand forecasting and inventory control through forecast collaboration. By sharing critical information with vendors, companies can reduce stock levels, maximize fill rates, and boost productivity. Enhanced communication keeps all supply chain partners aligned, resulting in better coordination and fewer misunderstandings, including vendor managed inventory.

Effective supplier collaboration:

● Minimizes risks and enhances the resilience of the supply chain.

● Helps businesses anticipate and mitigate potential disruptions, ensuring supply continuity.

● Uses joint performance metrics to allow both suppliers and buyers to track success and identify areas for improvement.

● Fosters a culture of continuous improvement and accountability.

Furthermore, collaborative relationships with suppliers can lead to significant cost savings and increased innovation. By working together, businesses and suppliers can co-innovate to improve products and processes while meeting sustainability goals. These collaborative partnerships not only drive sustainable cost reductions but also boost overall value and competitiveness in the market.

Choosing the Right Supplier Collaboration Platform

Selecting the right supplier collaboration software involves understanding your specific organizational needs and assessing how different platforms align with those needs. It’s essential to consider factors such as the size of your business, the complexity of your supply chain, and the specific features you require. A thorough assessment guarantees that the chosen platform will effectively support your collaboration processes.

Platforms can vary significantly in terms of pricing, features, and user accessibility. Therefore, it’s crucial to compare options before making a decision. Look for one platform that offers a good balance of functionality and affordability, and consider the ease of use for your team members. The right platform should be intuitive and accessible, enabling seamless collaboration with suppliers.

Mobile access to supplier collaboration platforms is a significant advantage in today’s fast-paced business environment. Many contemporary platforms offer mobile access, allowing you to manage supplier interactions on the go. This flexibility allows you to stay connected with suppliers and make informed decisions, no matter your location.

OpenBOM is the market leader when it comes to collaboration. It is the multi-tenant data management architecture that makes a difference. OpenBOM provides a “network layer” in data management architecture, which is extremely important for cross-company business processes and data intelligence capabilities. Without a multi-tenant data model, multi-tenancy is very limited to the usage of shared computing resources which limits overall SaaS benefits for the customers.

Real-Time Data Sharing and Visibility

Real-time data sharing is a game-changer for supply chain visibility and responsiveness. By providing up-to-date information on shipments, inventory levels, and material availability, businesses can better manage supply chain disruptions and make dynamic decisions to improve cost management. This real-time visibility allows for quick adjustments and ensures that all supply chain partners have relevant data access aligned.

Real-time shipment tracking combined with advanced analytics on visibility platforms enhances logistics operations. Utilizing technologies like GPS and telematics, these platforms provide up-to-date information on moving shipments, enabling businesses to track inventory management across all geographic locations. This comprehensive visibility helps mitigate operational inefficiencies caused by incomplete data and ensures smoother operations, ultimately aiming to improve visibility.

Centralized workflows further improve transportation execution by streamlining rate procurement and booking. Integrating real-time data sharing into operations allows businesses to quickly address supply chain disruptions, ensuring prompt and efficient resolution of issues. This level of transparency and communication is crucial for maintaining a centralized platform and an efficient supply chain.

Enhancing Supplier Relationships with Collaboration Tools

Collaboration tools are essential for enhancing supplier relationships, and they should include features like real-time communication, order management, and quality control. These tool facilitate open communication and trust, which are foundational to effective supplier collaboration. By fostering a culture of transparency and cooperation, businesses can collaborate to build stronger, more reliable supplier relationships.

Effective collaboration tools also aid in scenario planning, facilitating communication and coordination among different departments within a company. This ensures that all stakeholders, from procurement to production, are aligned and working towards common goals. Additionally, building collaborative relationships with business units can improve commitment to procurement policies and reduce instances of maverick spending.

Involving suppliers early in product development can lead to faster market introduction and improved product quality. By collaborating closely with suppliers from the outset, businesses can leverage their expertise and insights to innovate and create better products. This early involvement not only enhances product quality but also strengthens the overall supplier relationship, ensuring supplier readiness.

Streamlined Supplier Onboarding and Integration

Effective supplier onboarding is key to enhancing overall efficiency and productivity. Automation of processes associated with integrating new suppliers ensures smooth operations and reduces the likelihood of errors. A well-organized onboarding process fosters improved trust and collaboration with suppliers, setting the stage for a successful partnership.

Automated verification during onboarding ensures that suppliers comply with necessary regulations, minimizing fraud risks and ensuring compliance. Additionally, streamlined data management through automated systems maintains the accuracy and currency of supplier information, which is essential for effective collaboration and decision-making.

Integrating supplier onboarding tools with existing ERP systems can significantly simplify the onboarding process. Consolidating data and processes into a single platform ensures a seamless and efficient onboarding experience for new suppliers. This integration not only saves time and resources but also enhances the overall effectiveness of the supply chain.

AI-Powered Insights and Predictive Analytics

AI-powered insights and predictive analytics are revolutionizing supply chain collaboration by improving decision-making and response times to disruptions. Prioritizing platforms with advanced analytics capabilities provides organizations with valuable insights into supplier performance and operational efficiency. This strategic advantage enables businesses to stay ahead of the competition and adapt to changing market conditions.

Implementing AI solutions can lead to:

● A significant reduction in supply chain costs, with some organizations reporting an average decrease of 20%.

● Enhanced supply chain visibility by providing real-time insights. What if businesses could identify and address bottlenecks quickly?

● Smoother operations and better alignment with supplier capabilities.

AI also enhances scenario planning by processing complex data and generating rapid insights. Effective scenario planning helps mitigate risks by enabling businesses to anticipate and prepare for potential disruptions. The AI predictive analytics market is projected to reach USD 108 billion by 2033, indicating strong growth potential in this area. This growth underscores the increasing importance of AI in driving supply chain efficiency and resilience to improve forecast accuracy.

Enhancing Compliance and Reducing Maverick Spend

Enhancing compliance and reducing maverick spend are critical for maintaining supply chain visibility and efficiency. Embedded ESG and compliance tracking features focus on monitoring Scope 1-3 emissions, regulatory compliance, and supplier sustainability risks. Digitalizing supplier audits and compliance tracking helps businesses avoid quality issues and product recalls.

Sourcing collaboration optimizes procurement strategies, reducing the likelihood of maverick spend. Centralizing supplier engagement, contract negotiations, and spend analysis ensures better alignment with procurement policies and improves overall operational efficiency. This centralized approach not only enhances compliance but also drives continuous improvement in procurement practices.

Minimizing risks and ensuring efficient operations require effective collaboration with suppliers. Fostering a culture of transparency and accountability enhances decision-making and aligns procurement strategies with organizational goals. This alignment is crucial for maintaining a resilient and efficient supply chain, capable of adapting to changing market conditions and mitigating risk.

Case Studies: Success Stories in Supply Chain Collaboration

Deere & Company achieved a significant reduction in customer delivery schedules from ten days to five or fewer through a network redesign. This improvement in supply chain efficiency not only enhanced customer satisfaction but also demonstrated the power of effective supplier collaboration. By streamlining their operations and optimizing their supply chain processes to improve efficiency, Deere & Company set a benchmark for others to follow.

Intel managed to lower the order cycle time for its Atom chip from nine weeks to just two weeks, resulting in a $4 reduction in supply chain costs per unit. This remarkable achievement showcases the impact of standardizing processes and unifying technology onto a single platform. By leveraging the right supplier collaboration software, Intel was able to enhance its operational efficiency and reduce costs significantly.

Starbucks saved over $500 million by reorganizing its supply chain and managing its third-party logistics partners more effectively. Similarly, AGCO integrated a transport management system, leading to annual freight cost reductions of about 18% and improved logistics performance. These success stories highlight the transformative potential of supplier collaboration software in driving cost savings and enhancing supply chain efficiency.

Future Trends in Supply Chain Collaboration

The future of supply chain collaboration lies in the integration of technology and sustainability. Emerging supply chain models emphasize the importance of supplier collaboration to enhance operational efficiency and sustainability. Leveraging advanced technologies allows businesses to streamline supply chains and reduce environmental impact, aligning with global sustainability goals.

One notable trend is the reduction in the number of suppliers to streamline supply chains and foster deeper collaboration. Focusing on fewer suppliers enables businesses to build stronger, more innovative partnerships, driving collaborative solutions within the supply chain. This approach not only enhances operational efficiency but also encourages co-innovation and continuous improvement.

As businesses continue to navigate the complexities of the global market, the ability to anticipate and respond to potential issues will be crucial. Future trends in supply chain collaboration will likely focus on enhancing transparency, improving demand planning, and sharing order forecasts with suppliers. Embracing these trends helps businesses create more resilient and agile supply chains, capable of adapting to changing customer demand and market conditions, including effective supply plans.

Summary

The rapid evolution of supply chain collaboration software has transformed how businesses operate in 2025. By leveraging these advanced tools, companies can achieve real-time visibility, enhance supplier relationships, streamline onboarding processes, and harness the power of AI for predictive insights. The key benefits of supplier collaboration software, from improved communication and risk minimization to significant cost savings and innovation, highlight its essential role in modern supply chain management.

As we look to the future, the integration of technology and sustainability will continue to drive supply chain efficiency and resilience. By choosing the right supplier collaboration platform, businesses can foster deeper collaboration, enhance compliance, and reduce maverick spend. The success stories of industry leaders like Deere & Company, Intel, and Starbucks demonstrate the transformative potential of these tools. Embracing these advancements will enable businesses to stay competitive and meet the evolving demands of the global market.

Frequently Asked Questions

What is supplier collaboration software?

Supplier collaboration software is a digital tool that facilitates communication and coordination between businesses and their vendors, enhancing collaboration and efficiency in the supply chain.

How does supplier collaboration software improve supply chain efficiency?

Supplier collaboration software improves supply chain efficiency by enhancing communication, facilitating better demand forecasting, and optimizing inventory control, which collectively minimize risks and ensure a consistent supply.

What should I consider when choosing a supplier collaboration platform?

When choosing a supplier collaboration platform, prioritize your organizational needs and carefully compare features, pricing, and ease of use to find the best fit for your team. This approach ensures you select a platform that supports your objectives effectively.

How do AI-powered insights benefit supply chain collaboration?

AI-powered insights significantly enhance supply chain collaboration by improving decision-making, increasing visibility, and facilitating scenario planning, ultimately leading to reduced costs and improved efficiency.

What future trends are expected in supply chain collaboration?

Future trends in supply chain collaboration will likely focus on integrating technology to enhance sustainability and efficiency, reducing suppliers for deeper partnerships, and promoting innovation. Embracing these trends will be crucial for organizations aiming to stay competitive.