Barcode scans don’t fail because your handhelds forgot how to Wi-Fi. They fail because radio meets metal, height, motion, and interference—then roaming adds a split second of drama right as a picker hits “enter.” The fastest path to reliability isn’t a new controller or a louder SSID. It’s getting the cabling right so access points (APs) sit where physics works in your favor.

Why scans drop in warehouses (and what cabling has to do with it)

Warehouses are giant RF obstacle courses. Tall racking creates canyons that reflect and absorb signals. Pallets change daily, so a clean survey in an empty building tells a different story when SKUs arrive. If APs end up too high, signals skim along the ceiling and never land on the floor. If they’re centered over aisles without directionality, handhelds hear two or three APs equally well and roam at the worst moment—mid-transaction.

Cabling dictates where APs can actually live. If your copper runs only reach the roof steel, that’s where the radios will sit—twenty or thirty feet up, broad-beaming into the ether. Bring cabling down the column or on mid-bay struts and you can mount APs at practical heights, aim signal down the aisle, and reduce co-channel contention. Do the cabling right and roaming stops being a coin toss.

The cabling patterns that actually work

The simplest pattern is a star topology from your IDF/MDF: pull home runs to each AP location you’ve plotted on the design, with service loops for re-aiming and maintenance. In high-bay areas, add drop conduits so APs can mount 15–20 feet off the floor instead of on the ceiling steel. In very long aisles, run paired drops so you can alternate AP positions (end/mid/opposite end) without re-pulling cable when layouts change. For multi-building sites, terminate copper in local IDFs and haul fiber backbones to the core; this keeps PoE budgets stable and avoids voltage drop on long copper.

If your operation has a mix of free-movement zones and dense racking, plan two patterns: a grid for open areas (staging, packing, offices) and an aisle-centric pattern for storage. The grid uses evenly spaced drops to maintain consistent SNR; the aisle pattern prefers APs mounted at aisle ends or mid-points with directional antennas aimed down the lane. Where forklifts and scissor lifts are common, route cabling in rigid conduit with guarded drops and label every enclosure so techs don’t spend a shift hunting for “AP-Aisle-14-Mid.”

When you need a partner to execute this without guesswork, loop in a commercial network cable provider that understands warehouse mounting heights, PoE budgets, and fiber handoffs. The best cabling map wins before a single radio turns on.

Heights, antennas, and spacing: cabling for radio physics

Mounting height is the first fight you can win with cable. Most indoor APs with internal omni antennas behave best around 8–20 feet. Above that, energy spreads laterally and fades before it reaches handhelds at five feet off the floor. If your ceiling is 35 feet, don’t surrender—use cabling to bring the AP down on a bracket or column mount. Where the ceiling must be used, choose directional antennas and aim down the aisle to cut reflections and control cell size.

Spacing comes next. In open zones, a regular grid of AP drops prevents Swiss-cheese coverage and keeps cells tight enough that devices stay sticky to one AP until they truly need to roam. In racked aisles, plan for directional coverage that overlaps minimally at intersections, and cable both ends of long aisles so you can flip the pattern if inventory types change. Keep PoE budgets in mind: cameras and APs often share the same switch, so pair cabling design with a realistic power plan—especially if you’re adding readers, scales, or sensors later.

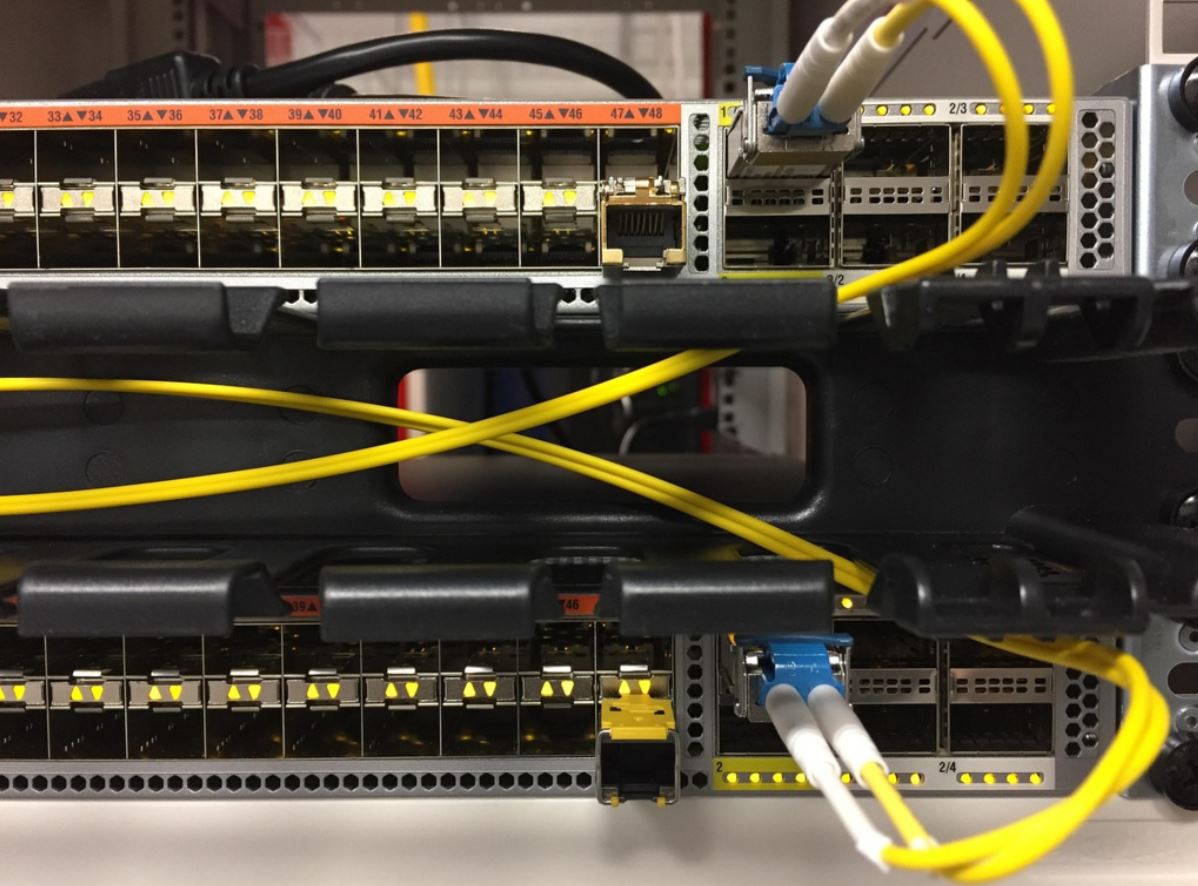

Don’t forget the backbone. Copper to APs, fiber between closets. That gives you multi-gig headroom for aggregation and removes distance limits for expanding sites. Mark spare strands in the fiber tray; you’ll thank yourself when a new cold room or mezzanine comes online.

Roaming, SSIDs, and segmentation: finish the job the right way

Cabling gets your APs into the right physical positions; a few configuration choices ensure scans don’t drop at the session layer. Keep SSIDs lean (two to three at most) and assign fast-roaming options your client fleet supports. Use 5 GHz/6 GHz where possible and limit 2.4 GHz to the devices that truly need it; the cabling pattern should reflect that plan, with cell sizes designed for your chosen bands.

Security and segmentation matter as much as RF. Warehouses increasingly blend scanners, tablets, cameras, and sometimes guest or contractor access. A simple, well-documented VLAN plan keeps OT traffic away from guest networks and isolates cameras from scanner traffic so video spikes don’t starve handhelds. For a baseline on WLAN safeguards—authentication, encryption, monitoring—pull from the NIST guidance on secure WLAN configuration, which maps cleanly onto enterprise Wi-Fi in industrial spaces.

Testing before go-live (and after the first re-slot)

Design is theory until forklifts roll. Validate with on-device tests, not just a survey cart: walk the actual pick paths and trigger scans at typical pauses—pallet pulls, aisle ends, dock doors. Note where latency spikes and adjust AP aim or channel plans rather than cranking transmit power. If you designed for both grid and aisle patterns, you’ll have spare drops where you can move an AP a few feet and change the outcome.

Cable certification matters too. Flaky terminations masquerade as “Wi-Fi problems.” Certify each copper run to its category rating, record PoE load tests per port, and keep a simple as-built: AP name, switch port, PoE class, antenna type, mount height, and photo. When inventory changes—especially metal-heavy SKUs—schedule a quick re-validation in those aisles. You’ll often fix issues by moving a single AP to the pre-cabled alternate position rather than redesigning the whole floor.

A quick example pattern you can copy

Imagine a 300,000-sq-ft DC with 42-foot clear height, six 300-foot aisles, and a busy staging area. Run fiber from the MDF to two IDFs at opposite corners of the racking block. From each IDF, pull copper to column-mounted brackets 18 feet high at aisle ends and midpoints—alternating ends per aisle for diversity (end A/mid/end B pattern). In staging, pull a square grid of drops at 12–15-meter spacing so seasonal surge stations can move without dead zones. Place spare drops at dock doors and the battery room; these become quick wins when more readers or cameras arrive.

When returns spike, you’ll add a temporary sorting zone. Instead of creative extension cords and ad-hoc APs, you’ll have live spare drops and a clear as-built so the network team can light the zone in minutes.

The takeaway

If you want scans to stick, fix the places cables land. Cabling that brings APs down to human height, favors aisle-aimed directionality where it counts, and backs closets with fiber will keep devices attached, roaming predictable, and throughput steady. Do the cabling like an RF engineer—and the Wi-Fi will behave like one.