In the last decade, supply chain resilience has moved from a buzzword to a survival metric. Global disruptions have exposed fragile networks, forcing leaders to scramble for digital solutions.

However, while companies pour billions into ERP upgrades and cloud-based analytics, a critical vulnerability remains overlooked: the physical infrastructure.

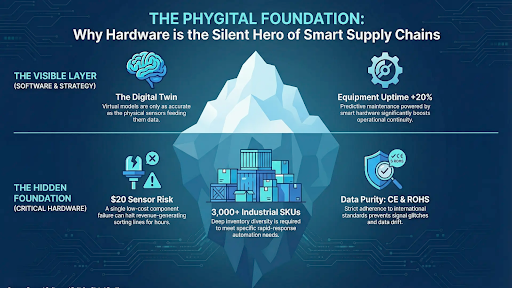

A “Smart Supply Chain” is not merely a digital construct; it is a complex marriage of software and physical hardware. The most sophisticated AI algorithm is rendered useless if the sensor feeding it data fails.

To achieve true operational resilience, logistics leaders must acknowledge that physical hardware—from proximity sensors to power supplies—is the bedrock of data accuracy and operational continuity.

The Rise of the “Phygital” Supply Chain

The modern warehouse is no longer just a storage facility; it is a “phygital” environment where physical actions are instantaneously converted into digital signals. The Internet of Things (IoT) has bridged the gap between the concrete floor and the cloud.

Every time a package moves on a conveyor belt, a photoelectric sensor triggers a timestamp. Every time an Automated Guided Vehicle (AGV) navigates a corner, it relies on precise signaling. These components are the sensory organs of the supply chain. Without them, the “digital twin” of your warehouse goes blind, severing the connection between what is happening on the floor and what is reported on the dashboard.

The “Hardware Gap”: Where Automation Often Fails

Despite the criticality of physical components, there is often a “Hardware Gap” in procurement strategies. Organizations frequently prioritize high-level software architecture while treating industrial sensors and switches as commodities to be bought at the lowest price.

This is a false economy. In a 24/7 fulfillment center, the failure of a single $20 sensor can halt a sorting line that generates thousands of dollars in revenue per hour. Downtime does not just affect throughput; it creates a ripple effect, delaying shipments, skewing inventory data, and ultimately damaging customer trust.

Critical Component Standards for 24/7 Operations

To close the hardware gap, procurement must shift focus from cost to compliance and capability. In the realm of automated logistics, component availability and certification are non-negotiable.

Industrial environments are harsh; components must withstand vibration, dust, and temperature fluctuations. This is why strict adherence to international standards (such as CE and ROHS) is mandatory for procurement. Furthermore, the complexity of modern machinery requires a vast array of specific parts. Industry manufacturers like Omch emphasize that maintaining a catalog of over 3,000 distinct automation SKUs—from proximity sensors to DIN-rail power supplies—is necessary to meet the specific, rapid-response needs of modern global supply chains.

Ensuring your supplier has both the regulatory certifications and the depth of inventory (SKU diversity) is the only way to safeguard against supply shocks.

Data Integrity Starts at the Source

There is an old adage in data science: “Garbage In, Garbage Out.” In the context of AI-driven logistics, this is paramount. Predictive analytics models rely on the purity of input data.

If a voltage fluctuation causes a sensor to misfire, the ERP system receives incorrect data. Over time, these minor inaccuracies accumulate, leading to “data drift.” High-quality hardware ensures signal integrity. When a sensor reports a blockage, it must be a real blockage, not a hardware glitch. Investing in precision hardware is, effectively, investing in data governance.

Future Trends: Predictive Maintenance in Logistics

The ultimate goal of integrating high-quality hardware is to move from reactive repairs to predictive maintenance. Instead of waiting for a breakdown, smart components can now signal when they are nearing the end of their lifecycle.

The shift towards predictive maintenance is not just a theoretical concept but a financial imperative. According to a widely cited report by Deloitte, predictive maintenance strategies can increase equipment uptime by up to 20% and reduce material costs significantly. By integrating smart sensors that communicate real-time health status to the central supply chain system, managers can schedule repairs during planned downtime, ensuring the fulfillment process remains uninterrupted.

Key Takeaways

| Area | Key Takeaway | Impact/Data |

| Risk | Low-cost hardware is a false economy. | $20 sensor failure halts revenue-generating lines. |

| Data | Physical sensors dictate AI/ERP accuracy. | Glitches cause “Data Drift” & blind digital twins. |

| ROI | Switch to predictive maintenance strategies. | Increases equipment uptime by up to 20%. |

| Sourcing | Mandate strict certification (CE/ROHS) & SKU depth. | Requires vendors with 3,000+ automation SKUs. |

Conclusion

As supply chains become increasingly automated, the line between hardware and software blurs. For logistics directors and operation managers, the strategy for the coming year is clear: stop viewing hardware as a commodity. By prioritizing industrial-grade reliability, diverse SKU availability, and rigorous standards, you build a supply chain that is not just smart, but unshakeable.