For a long time, planning freight routes was pretty straightforward. You’d set a route, and that was pretty much it. The trucks had their routes and times all set when they drove out of the yard.

We can actually deal with problems as they come up. That way of doing things was fine back when traffic wasn’t so crazy, and delays didn’t happen all the time.

Things are just really different for supply chains these days. When you’ve got unexpected traffic, crazy storms, ports all backed up, or even new city rules, trying to stick to one route can really mess things up and cost you a lot. The old way of routing just can’t keep up anymore.

Why Rigid Routing Creates Headaches

So, why does sticking to rigid routing often create such headaches? When we just use fixed routes, even a small issue somewhere can cause delays that mess up the whole system. When trucks get stuck in traffic or a wreck and can’t change their routes, deliveries end up being late. That just means more money spent on detention fees, extra fuel sucked up, and a bunch of pretty annoyed drivers.

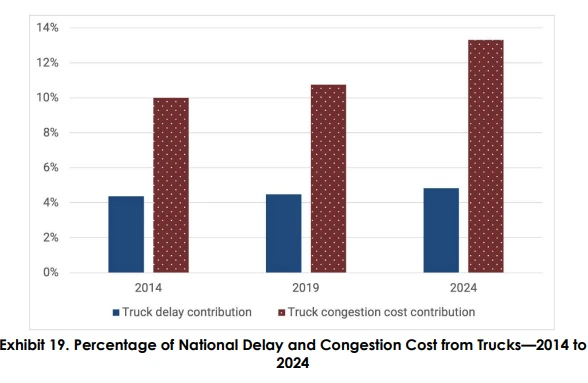

The Texas A&M Transportation Institute found that the trucking industry is losing around $36 billion every year, mainly because of lost productivity and wasted fuel. That number really shows how much money gets wasted when we stick with old ways of doing things.

Yeah, static routing pretty much ignores what’s going on with the roads or what drivers are running into. Dispatchers are always behind the curve without live updates. By the time they hear about delays, they’ve already happened. It’s really hard to keep up and handle everything smoothly.

Real Life Doesn’t Follow a Script

Sometimes, things in real life just don’t go according to plan. Think about a driver, with the sun just peeking over the horizon, about to start a huge trip, like driving across several states. Halfway through the drive, a bunch of trucks got into a crash. This pretty much shut down part of the interstate for many hours. If you’re on a fixed path, a tiny issue can seriously mess up everything. You’ll miss when things are supposed to arrive, need to set up new delivery times, and just waste more time.

Think about city deliveries, for instance. Sometimes, local rules pop up unexpectedly, limiting where trucks can pull over. A really strict plan doesn’t give you any wiggle room to see those last-minute problems coming, or even a way to get around them.

When ports and terminals get backed up, it causes problems throughout the whole system. When there’s a boat delay or a gate gets jammed, you can end up waiting for hours, and regular estimated arrival times just don’t account for that. Think of it this way: the more steps you add to your plan, the easier it is for the whole thing to break.

The Shift to Real-Time Routing Technology

The big change to real-time routing technology is a pretty interesting one. Luckily, there’s a better way to do this now, thanks to technology. It’s pretty amazing how quickly real-time data is getting better and connecting into systems that can actually think and do things while trucks are still on the road.

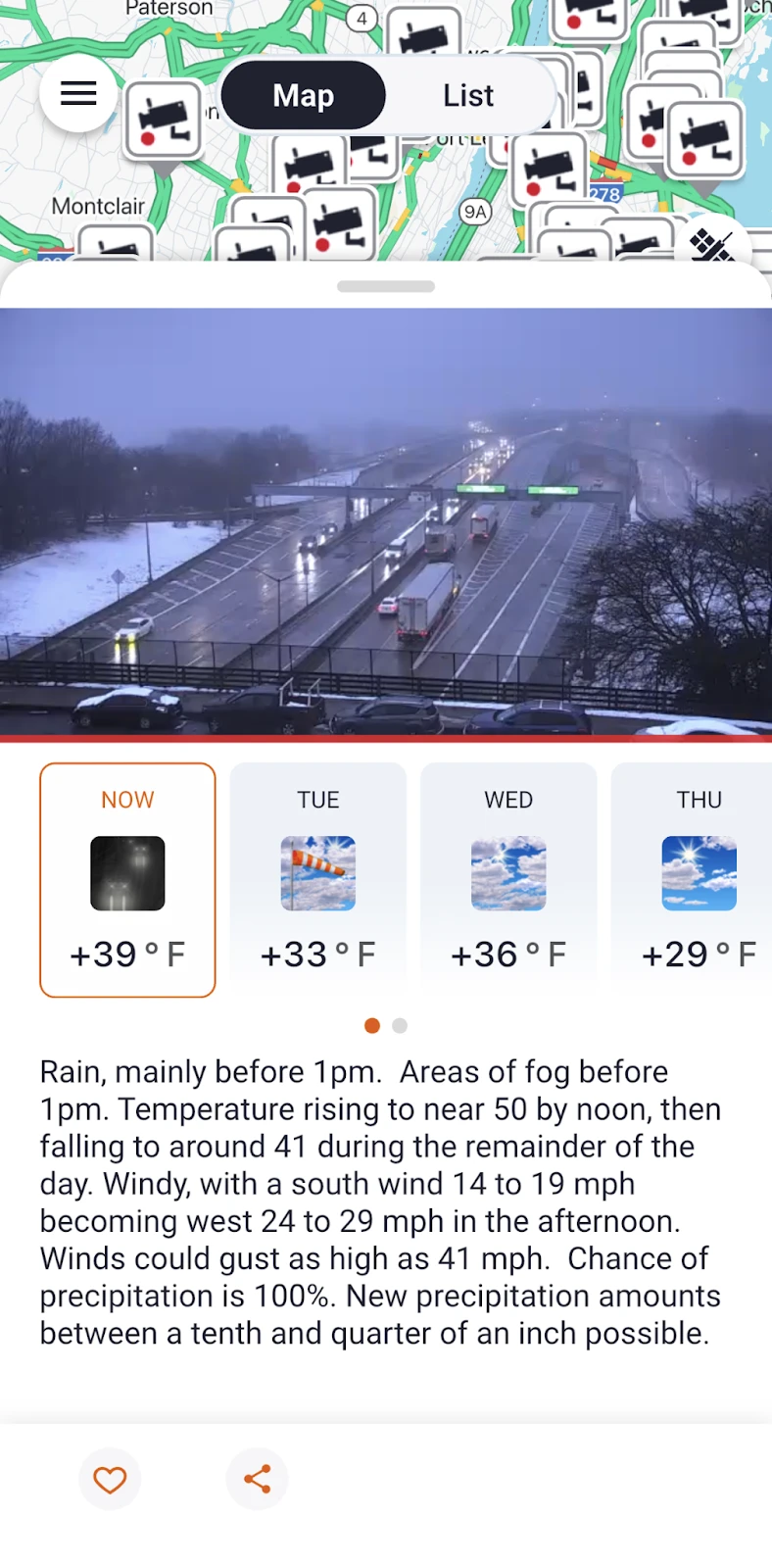

So those traffic cameras that Transportation Departments use? They’re now being used for live updates on what’s happening. So, when you mix these updates with stuff like telematics, what drivers are actually doing, weather forecasts, and reports about accidents, you get a really clear idea of what’s going on out there on the road.

Today’s trucker navigation apps are way more than just a line on a map. They put a bunch of different signals together. This lets them change routes on the fly, keeping in mind things like what kind of cars can go where, what’s being carried, and when customers are expecting their deliveries.

Think about something like Trucker Guide. It’s a great example of how things are changing, taking info from cameras and driver performance to help fleets make smart decisions about their routes.

What’s In It for Fleets and Shippers?

So, what’s in it for fleets and shippers? Going with adaptive routing really makes a difference, you can see. A report from McKinsey in 2022 suggested that by using dynamic routing, companies could cut freight costs by 5 to 10 percent. It also found that this could make deliveries on time up to 20 percent more often.

You save money because you’re using less fuel, avoiding detention fees, and simply making better use of your stuff.

Behind it, adaptive routing really makes things better for the workers. Drivers spend less time looking for other ways to go or for spots to park, and that helps keep them from getting too stressed out and eventually quitting.

When carriers and shippers have a clearer idea of what’s coming, it really helps build stronger customer relationships and cuts down on all those arguments.

Quickly Figure Out Your Potential ROI

Just doing a quick check on the return on investment can really help us figure out where to put our money first.

Okay, so imagine a single trip, right? Like one haul, and everything it takes to get it done – the gas, what the driver earns – all that comes out to $1,500. When dynamic routing cuts down unplanned idle time by 10 percent, you get to save $150 on each trip.

When you multiply that by how many trips you take each week, and then by the size of your fleet, those savings really add up quickly. When you consider the lower fees for holding goods and better use of what you have, it really makes a strong argument for trying out some pilot programs.

Here’s How to Get It Done

Here’s how to actually get this done: Take a look at your data sources: make a list of everything you’re already getting from things like telematics, ETA providers, weather services, and public traffic feeds.

My advice? Just start small. Pick one route or a few trucks and really test out dynamic rerouting in the real world.

So when we make route changes in real-time, everyone on the dispatch, billing, and customer service teams needs to see them right away.