The year 2020 has thrown us all for a loop, and the resulting drastic shifts in demand are motivating companies to accelerate the digital supply chain transformations that for some may have been languishing in early stages. Walmart’s senior vice president of supply chain, product and engineering recently commented that the events of 2020 have “forced us to innovate at a speed that I had not seen before”. The more complete end-to-end data and improved supply chain visibility that come with digital transformation help companies adapt to rapidly shifting demand so they’re ready for whatever tomorrow will bring.

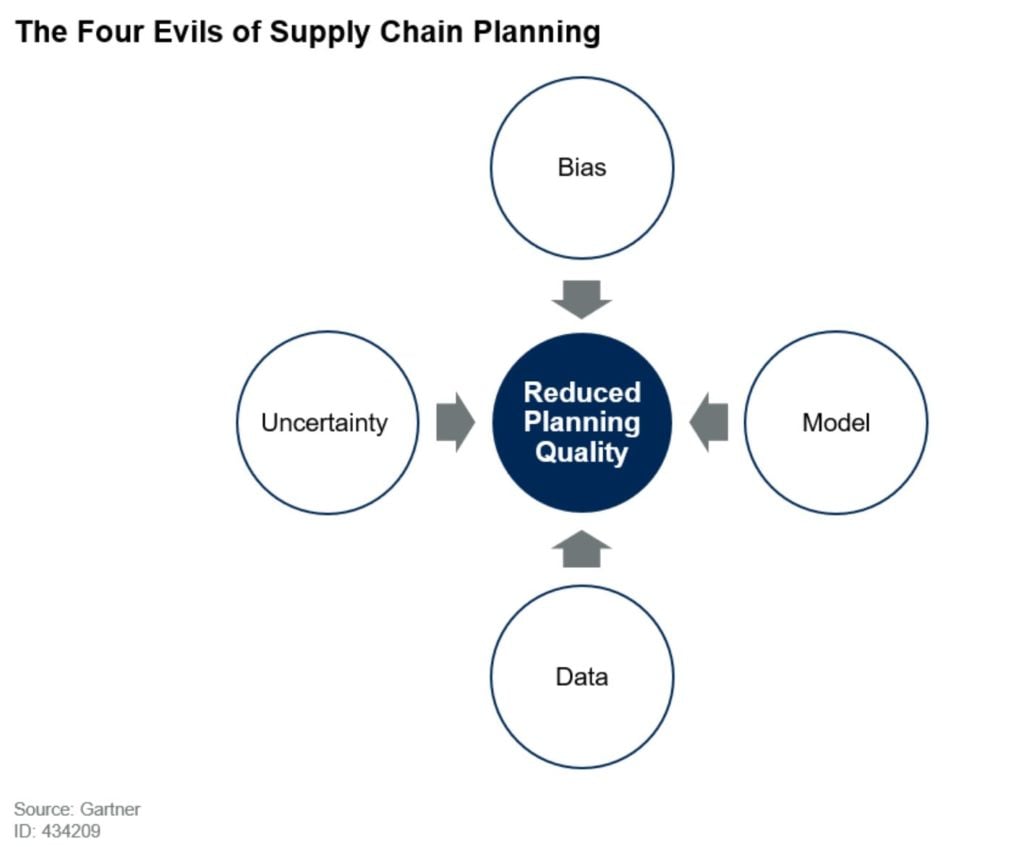

Of course, we all know that digital supply chain planning transformation still doesn’t happen overnight. A clear roadmap and guideposts along the way are helpful to ensure the rewards will be worth the effort. Gartner’s report, Digital Supply Chain Planning: The Art of the Possible Should Focus on Reducing the Four Evils of Planning encourages supply chain practitioners to stay focused on the four “evils of planning” and how digital planning can help vanquish them and produce higher plan quality, at every stage of the journey.

Reduce these Planning Evils for Better Plan Quality

We believe the report urges companies to keep theirsupply chain planning investments focused on these four evils/areas in every step along the journey as the best way to improve quality of planning decisions and maximize achievement of planning goals.

Gartner outlines a progressive plan for how to focus on the four evils in each stage in digital planning maturity. We’re highlighting only a small sample of Gartner’s recommendations here, beginning with Stage 2 because this is really where digital planning begins.

Stage 2 Digital Planning: Confirm You Have the Following Initiatives in Your Short-Term Digital Planning Roadmap

- Uncertainty: The evil of uncertainty is the biggest focus at this stage of digital planning. A great place to begin is to get started using machine learning for demand planning. An example is to improve accuracy of short-term demand forecasting using other sources of demand data such as point-of-sale and external causal factors.

- Bias: Increasing planning automation at this early stage reduces human intervention and therefore the risk of introducing bias into planning decisions.

- Data: While planning data at this stage still has a high degree of latency, you can still improve data quality using machine learning to, for example, clean and correct demand history.

- Model: You likely still have several different planning models in place at this stage, but you can use machine learning here to better predict lead times and variability to improve the quality of models used for replenishment and production plans. Machine learning can also help you better understand seasonal- or location-specific delivery time fluctuations to improve delivery reliability.

Stage 3 Digital Planning: Justify the Following Initiatives for Your Midterm Digital Planning Roadmap

- Uncertainty: Here your focus is to manage variability on the supply side. You can begin to link up the functional machine learning initiatives you began in Stage 2. For example, sending machine learning-derived demand signals upstream in the supply chain. This allows for further value because of improved forecast accuracy.

- Bias: Keep automating more planning decisions to further reduce human bias. One way to do this is for planners to begin using machine learning to recommend the “best” supply chain response based on historical planner supply responses.

- Data: Focus on how data is linked across the end-to-end supply chain and how fast it propagates through the supply chain model. Cloud-based solutions and in-memory computing can increase the speed of planning.

- Model: Create an improved single model of the supply chain for use by planning analytics. Some companies may begin testing a supply chain twin at this stage.

Stage 4 Digital Planning: Establish a Group to Start Experimenting on These Initiatives

- Uncertainty: This stage is a key point in your digital transformation as you focus on extending the scope of planning within your company and with customers and suppliers. Armed with a better understanding of variability, more data and increased computing power, you can move from just one plan to calculating many alternate plans, which is characteristic of resilient supply chain planning and a move away from a deterministic to a stochastic, or probabilistic, plan.

- Bias: As use of machine learning increases you start to enable prescriptions that are optimally based, instead of what human planners have thought are the right responses in the past.

- Data: Granular and near-real-time data is being utilized to feed the digital supply chain twin. You may even begin to incorporate IoT signals.

- Model: The digital twin is at the core of the planning technology and is closer to mirroring the actual physical supply chain.

Stage 5 Digital Planning: Complete the Transformation of Your Digital Planning Vision With These Initiatives

- Uncertainty: At this stage you have a high level of understanding of the underlying causes of variability across the supply chain, resulting in a much lower level of uncertainty.

- Bias: At this stage the degree of automation is high—90-95% of everyday planning decisions are autonomous; planners can focus more on experimentation to identify new ways to improve planning KPIs.

- Data: All forms of data can be easily incorporated into the digital supply chain twin as needed. Data lakes may also be leveraged.

- Model: The digital supply chain twin is fully evolved and different layers of the model can be connected within and outside the organization.

No matter where you are in your journey, the important thing is to stay laser focused and keep moving. For the full detail on how to keep your digital planning transformation moving in the right direction, click below to get your complimentary copy ofGartner’s report: Digital Supply Chain Planning: The Art of the Possible Should Focus on Reducing the Four Evils of Planning.

GARTNER is a registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally, and is used herein with permission. All rights reserved.