In a period where the mechanical headway is moving dangerously fast, organizations need to adjust rapidly or risk falling behind. The way to remain ahead is persistent development, and the most common way of rejuvenating groundbreaking thoughts is advancing quickly. Perhaps one of the most groundbreaking apparatuses in present-day item improvement is fast prototyping. It’s reshaping ventures, assisting organizations with testing ideas quicker, refining plans all the more actually, and getting their items into the market with more prominent speed and exactness.

Yet, what is fast prototyping, and how could it be molding the eventual fate of development?

Understanding Rapid Prototyping

At its center, fast prototyping alludes to the utilization of trend-setting innovations, similar to 3D printing or added substance fabricating, to rapidly make an actual model of an item plan. This approach permits specialists, fashioners, and makers to take computerized models and transform them into substantial models surprisingly fast or in days, not weeks or months. Dissimilar to customary prototyping, which includes tedious cycles like shape creation or machining, quick prototyping offers a quicker and more savvy technique for testing and refining item thoughts.

The capacity to transform a thought into an actual model in such a short measure of time permits organizations to improve rapidly, try different things with new ideas, and eventually speed up the improvement of new items.

The Benefits of Rapid Prototyping

Speed and Effectiveness Being Developed: One of the main advantages of fast prototyping is speed. The conventional strategies for making models can be slow and exorbitant, particularly while managing complex plans. With quick prototyping, organizations can lessen the time it takes to foster models from weeks or months to only a couple of days. This speed is fundamental in businesses where time-to-showcase is urgent, like innovation, auto, and purchaser gadgets.

Cost-Adequacy: Prototyping can be costly, especially when the plan requires custom tooling, shape, or concentrated gear. Fast prototyping dispenses with a significant number of these forthright expenses by utilizing computerized records and 3D printing to straightforwardly make models. This permits organizations to analyze and repeat plans without burning through every last dollar. Moreover, because the models are made on request, organizations can stay away from the monetary gamble of putting vigorously in a plan that may not work. Techniques like rapid molding are particularly effective for creating precise prototypes quickly, helping businesses save time and reduce upfront costs.

Expanded Adaptability and Emphasis: Fast prototyping offers planners and specialists the adaptability to test various forms of an item and make changes rapidly. Whether it’s changing the shape, size, material, or even usefulness, models can be modified and republished quickly. This iterative cycle is pivotal for refining items before they enter full-scale creation, guaranteeing they satisfy the expected guidelines and are liberated from configuration imperfections.

Better Coordinated Effort and Correspondence: Making an actual model from the get-go in the planning cycle gives groups an unmistakable reference to work with. Whether it’s specialists, fashioners, or advertisers, having a model to examine and look at takes into consideration more clear correspondence and better-coordinated effort. This involved methodology works on the probability of getting plan blunders early and furnishes partners with a clearer vision of the result.

Upgraded Item Testing and Approval: The capacity to rapidly make models additionally considers greater testing. Whether it’s convenience trying, ergonomic testing, or execution testing, models give significant experiences into how an item will act in certifiable situations. Organizations can direct tests before the planning cycle, permitting them to approve their ideas and make upgrades before moving to large-scale manufacturing.

Industries Revolutionized by Rapid Prototyping

Quick prototyping isn’t restricted to only a couple of enterprises – it’s changing many fields. Here are only a couple of instances of enterprises that are seeing critical advantages from quick prototyping:

Medical care:

In medical care, fast prototyping has opened up additional opportunities for modified clinical gadgets, inserts, and prosthetics. For instance, 3D printing takes into consideration the production of patient-explicit prosthetics that are more agreeable and more qualified to individual requirements. Clinical gadgets can likewise be prototyped and tried rapidly, lessening the time it takes for new medicines to arrive at patients.

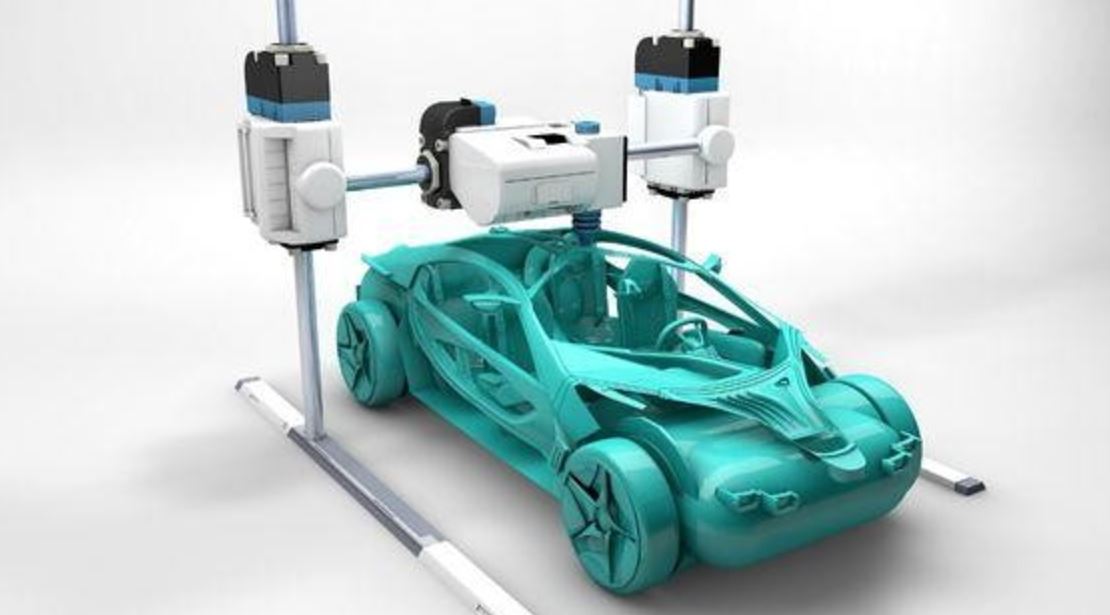

Car:

The car business has long depended on prototyping to test new parts and plans. Quick prototyping speeds up the plan and testing stages, permitting makers to explore different avenues regarding more intricate plans. For example, vehicle parts that were already difficult to produce because of their intricacy or material necessities can now be prototyped and tried with no sweat.

Purchaser Gadgets:

The tech business flourishes with fast development, and quick prototyping is critical to keeping up. Organizations in customer gadgets utilize fast prototyping to rapidly create and test new items, from cell phones to wearables. This permits them to refine their plans and offer new items for sale to the public quicker, staying aware of customer interest and mechanical progressions.

Aviation and Protection:

In aviation, quick prototyping is utilized to create and test parts for airplanes and shuttles. The accuracy and speed it offers assistance guarantee that basic parts are tried before they are utilized in perplexing and high-risk conditions.

Overcoming Challenges with Rapid Prototyping

While quick prototyping offers many advantages, it isn’t without its difficulties. One of the essential limits is the material utilized in 3D printing. While there have been huge advances in materials accessible for prototyping, the strength and solidness of models may not necessarily match that of the result. Accordingly, organizations should once in a while direct extra testing or utilize cross-breed prototyping techniques to guarantee the eventual outcome fulfills the required guidelines.

Also, not all items or plans are appropriate for quick prototyping. Complex parts that require very exact or unpredictable assembling strategies might in any case require conventional techniques for full creation. Nonetheless, as innovation progresses, the hole between fast prototyping and customary assembling techniques proceeds to tighten, and more businesses are tracking down ways of incorporating quick prototyping into their work processes.

Why Choose a Rapid Prototyping Company?

For companies looking to leverage the full potential of rapid prototyping, partnering with a trusted rapid prototyping company can make a world of difference. These companies have the expertise, technology, and resources needed to produce high-quality prototypes quickly and efficiently. Whether you’re developing a new product or refining an existing design, a professional rapid prototyping company can help streamline your product development process and bring your ideas to life faster.

Numerous fast prototyping organizations likewise offer a scope of administrations, including 3D printing, CNC machining, and infusion shaping, guaranteeing that organizations have the adaptability to pick the best technique for their particular requirements. By working with these organizations, organizations can exploit their industry information and cutting-edge innovation to push the limits of advancement.

The Future of Rapid Prototyping

Looking forward, the fate of fast prototyping is inconceivably encouraging. As new materials are created and printing innovations keep on improving, the speed, precision, and adaptability of quick prototyping will keep on advancing. From bigger and more mind-boggling plans to additional feasible materials, the up-and-coming age of fast prototyping is set to alter many more businesses.

Before long, we can anticipate that fast prototyping should assume a much bigger part in the item improvement process, particularly as organizations progressively search for ways of accelerating development and decreasing costs. The conceivable outcomes are inestimable, and as innovation progresses, so too will the potential for quick prototyping to shape the fate of advancement.

Wrapping Up

Quick prototyping is reshaping how organizations approach item advancement. By offering a quicker, more financially savvy, and adaptable method for testing and refining item plans, it’s assisting organizations with improving more rapidly than at any other time. Whether you’re in medical services, a car, customer hardware, or some other industry, quick prototyping can smooth out your improvement cycle and rejuvenate your thoughts quickly. Joining forces with a fast prototyping organization can assist with opening the maximum capacity of this groundbreaking innovation and move your business forward in the cutthroat scene of development.